EPA-306 | Collar Trimming, Turning, and Blocking Machine

Collar Trimming, Turning, and Blocking Machine

Description

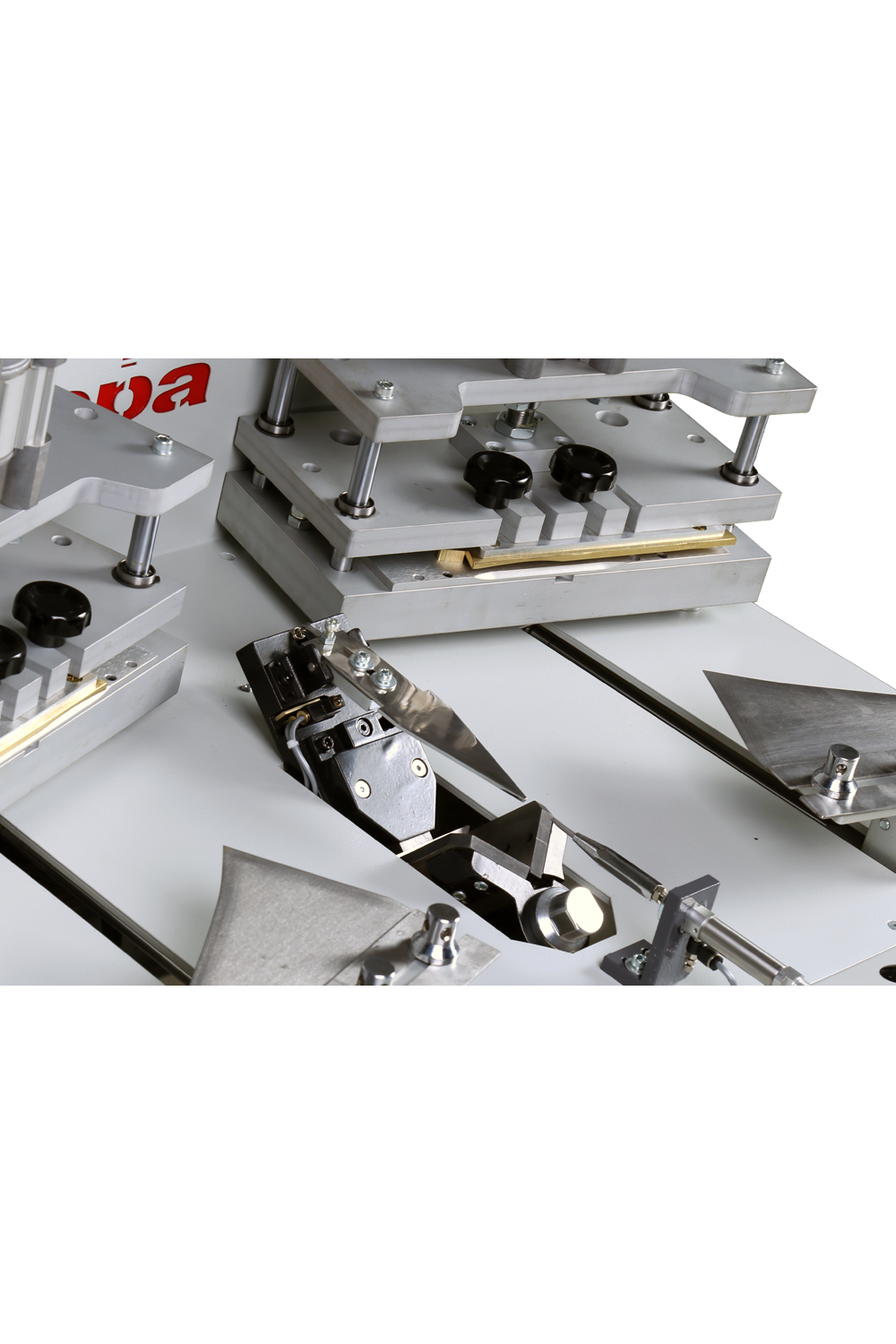

The EPA-306 Collar Trimming, Turning, and Blocking Machine is an advanced garment finishing solution designed for precise collar shaping, trimming, and pressing in shirt and blouse production. This machine integrates a collar turning and trimming system, ensuring perfectly shaped and standardized collar points with minimal fabric distortion.

Equipped with a special cylinder structure, it precisely centers the pressure needle and follow-up mirror, providing gentle fabric handling to prevent deformation. The high-strength, special alloy blades offer long-lasting durability, while the automated air-cleaning system removes waste fabric from the knives, ensuring a smooth and uninterrupted trimming process.

The new pressing system shapes collars flawlessly, while the automatic mold carrier provides consistent and standardized pressing for collar points. Featuring an adjustable digital temperature control, the machine adapts seamlessly to different fabric types, ensuring high-quality results even on delicate materials.

Designed for efficiency, the machine includes an easy toggle switch for single and dual pressing, along with separate adjustable pressing time control for both modes. The quick mold-changing system enhances productivity, reducing downtime. Optional features such as a digital display and collar holder system further optimize precision and usability.

For enhanced automation and safety, the PLC-controlled machine comes with multiple operator protection features and a CE certification, making the EPA-306 Collar Trimming, Turning, and Blocking Machine an essential addition to any garment manufacturing facility.

Feature